Overview

The development of models for outbound baggage systems is a significant focus of our simulation team. We generally conduct two types of simulations:

- Model an existing system to validate its performance and identify improvements to enhance efficiency and capacity.

- Model a new baggage system in collaboration with our design team to determine the optimal layout.

When simulating an outbound baggage system, various components must be considered:

Demand Forecasting

Realistic demand forecasting is crucial when modeling a baggage system. A bag-by-bag forecast of passengers and bags arriving at check-in counters is developed using either historical airport/air carrier arrival patterns or arrival distributions endorsed by TSA. For transfer bags, we utilize arrival and departure schedules, along with historical hourly data on connection times, to build a flight-to-flight forecast. This helps accurately assess how long a bag remains in the baggage system, which is essential for sizing outbound bagrooms, bag stores, and batching stations.

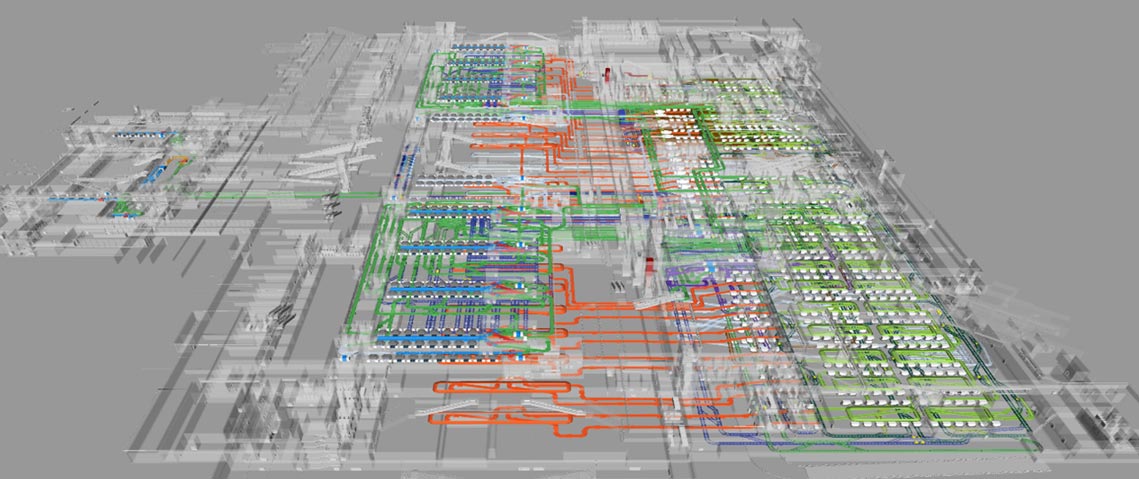

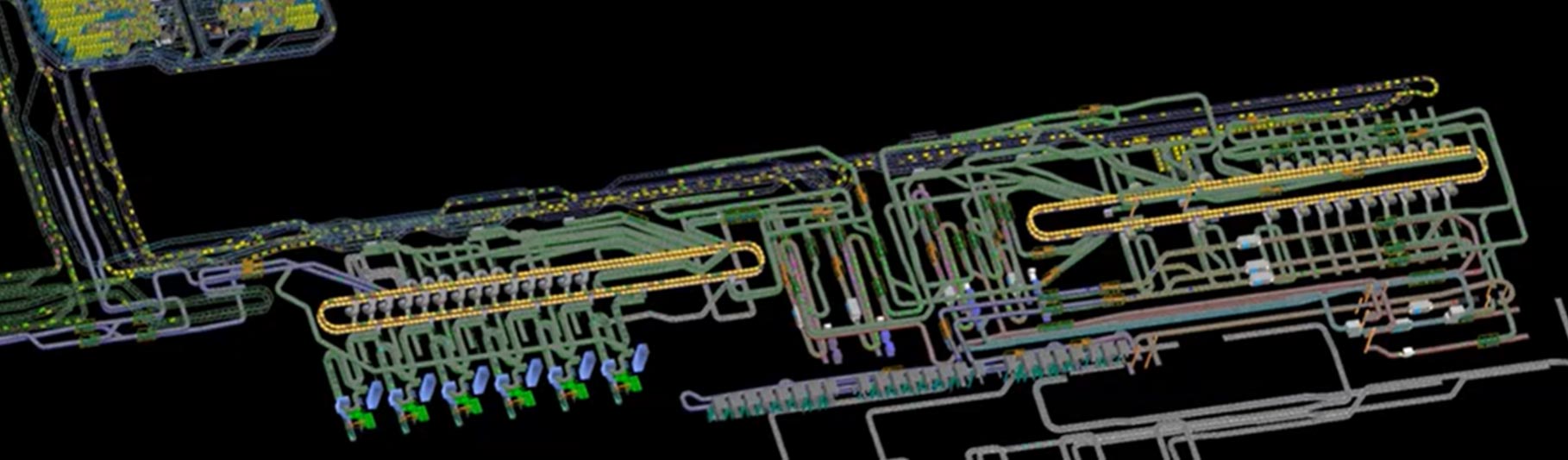

Model Development

Using 3D simulation software (such as AutoMod and Simulate 3D), BNP creates a digital twin of the baggage system. These models reflect the existing or proposed layout and operational characteristics of each component.

The components typically include:

- Check-in processes, kiosks, and automated bag drop stations

- Baggage screening equipment (e.g., CT and Trace Detection) following specific screening protocols such as TSA PGDS Guidelines, International Standard 3 protocols, or other relevant protocols

- Conventional conveyors

- Tilt-tray sorters

- Vertical merges and vertical sorters

- Individual carrier systems, including empty carrier storage, stackers, and de-stackers

- Transfer induction lines

- Batching stations

- Merges

- Early bag storage (EBS)

- Makeup devices

System Calibration and Validation

For existing systems, models are validated against historical performance data. For new systems, validation is conducted by reviewing the simulation’s performance with system experts.

Where applicable, the models may also include both inbound and outbound transfer ramp vehicles that deliver bags from the bagroom to aircraft and vice versa. The models help evaluate the system’s ability to meet defined performance goals under various conditions, such as:

- Proposed design configurations and improvements

- System capacity for accommodating growth

- Performance under fault conditions

- Impact of operational changes

- When the system will reach capacity

For design improvements or alternatives proposed by BNP, iterative evaluations are performed with the Design Team to ensure the baggage system meets the required performance goals.