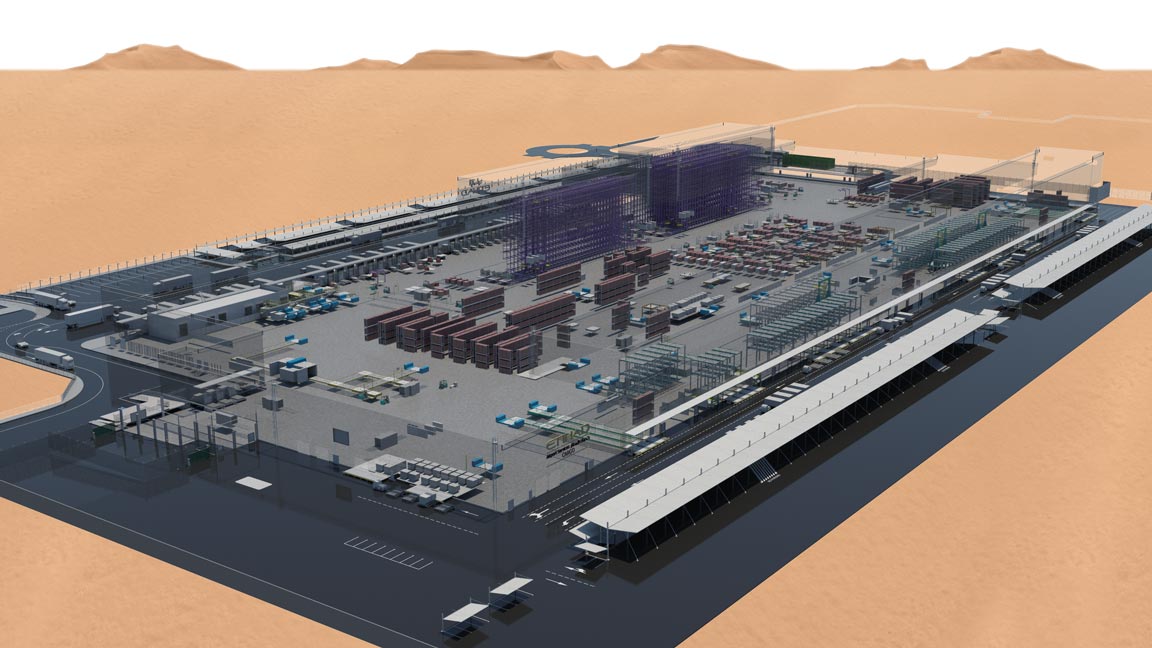

Overview

Etihad Airport Services Cargo (EASC) retained BNP to analyze historical cargo transactions to provide a foundation for detailed system design. To support this process, we developed a 3D simulation model for the cargo handling facilities at Abu Dhabi International Airport. These facilities have an annual capacity of 2.5 million tons.

Data Analysis and Forecasting

We conducted extensive data analysis of existing cargo records. This helped us determine detailed forecasts for each product category for the new cargo terminal design. We calculated the forecasted cargo demand for peak days and peak hours. These forecasts served as the basis for the facility’s detailed system design and for evaluating the design through simulation.

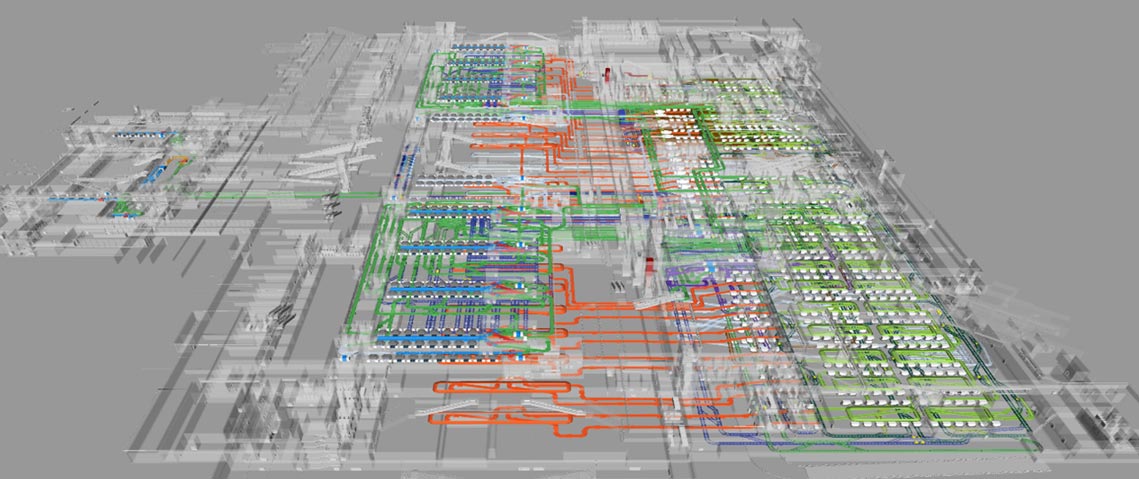

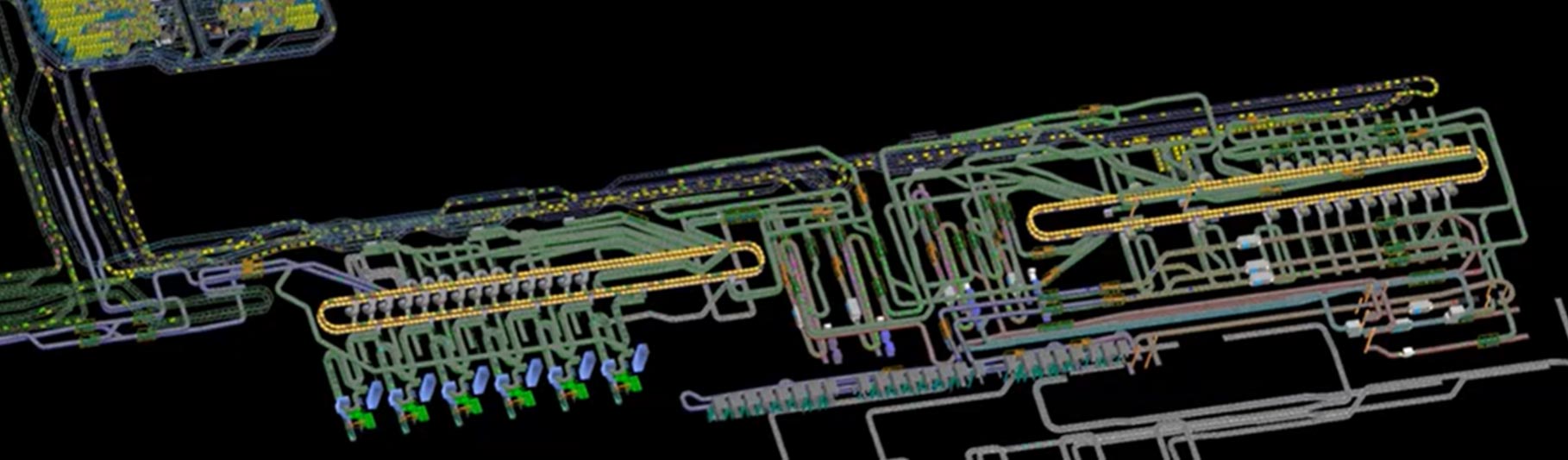

Simulation Development

Based on the detailed system design, a simulation model was developed for the air cargo processing and sorting center. This simulation incorporates automated material handling systems that can process 2.5 million tons of cargo each year. The simulation was used to evaluate facility performance, optimize operational workflows, and test various ‘what-if’ scenarios to ensure robust efficiency.

Functional Areas

Functional areas modeled include landside delivery acceptance, security and customs screening, consignment binning, Automated Storage and Retrieval System (ASRS) bin storage, automated Unit Load Device (ULD) storage, ULD build and break workstations, cool storage, dangerous goods storage, and ULD airside interfaces. Key terms: ASRS (Automated Storage and Retrieval System), ULD (Unit Load Device).