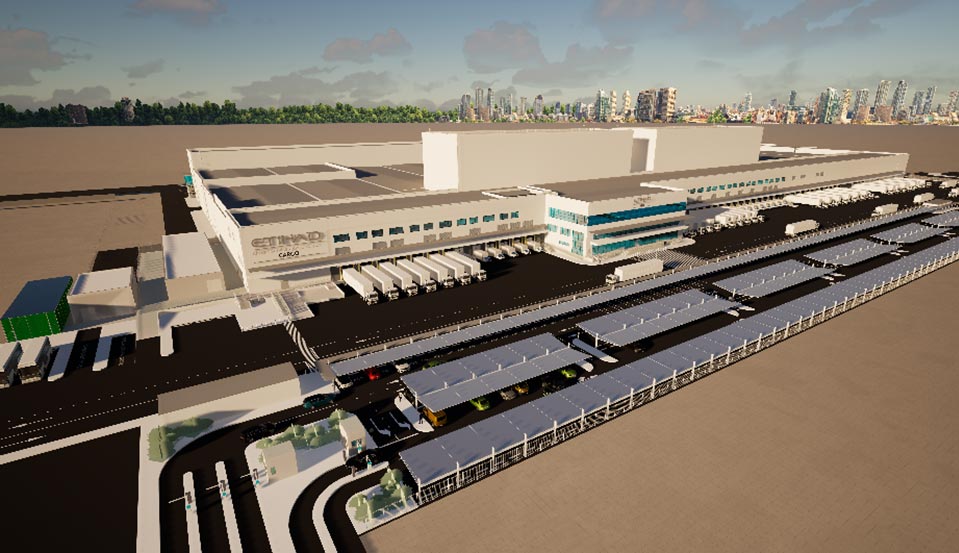

Overview

MATAR has retained BNP and the leading Middle East A&E firm Dar Al-Handasah for the design, engineering, tendering, and construction administration services for a new air cargo terminal (Terminal 2). At 3.3 million tons per annum, DOH will rank in the top 3 cargo terminals in the world for capacity.

E-commerce and Courier System

E-commerce and related courier delivery flows represent a significant growth area in air cargo. As part of this project, an automated mail and courier handling system is being developed to provide the following functions:

- Security screening (selective, based on the originating and destination pairing)

- Screening for dangerous goods (e.g., lithium batteries)

- Automated sortation

- Automated item-level storage (for mailbags or courier items)

PROJECT DETAILS

System Design

The system has three entry points where items are automatically identified, then moved by conveyors through screening machines to a cross-belt sorter and collection chutes. Items are stored individually by placing them in carriers, which are kept in an Automated Storage and Retrieval System that releases carriers when needed.

Capacity and Expansion

The system is designed with a single main sorting loop, but can be expanded to include a second sorter and additional chutes later to handle more items or provide backup. It can process up to 2,700 items per hour (limited by screening), with storage space for about 1,000 items.

Integration

The mail and courier system also uses the airport’s large ULD handling system to store and move unit load devices between the ground floor and the second-floor mail and courier area.