Overview

In anticipation of increasing air traffic and the need to implement ECAC Standard 3 screening requirements, Copenhagen International Airport (CPH) planned a redesign of the existing Baggage Handling System (BHS) to enhance both screening compliance and capacity.

System Design and Planning

BNP verified the BHS requirements for a Standard 3 Hold Baggage System (HBS) and evaluated the airport’s projected development through 2040. We proposed a phased conversion of the screening and sortation system in Terminal 2 and the screening system in Terminal 3 into common-use facilities. This approach fulfilled the screening requirements while optimizing the number of required machines and improving the efficiency of existing baggage make-up areas.

Capacity Expansion

Additionally, BNP proposed the construction of a new make-up facility on the west side of the airport to further increase system capacity in anticipation of future demands. The screening machines in Terminal 3, used for transfer baggage, were also evaluated for replacement to meet non-Schengen transfer capacity.

Future-Proofing

At the conceptual stage, provisions were made for future equipment integration—such as screening machines and conveyor Rights-of-Way (ROWs) in Terminal 3—to ensure seamless scalability toward the 2040 development stage. Throughout the project, BNP worked closely with CPH to align BHS requirements within the constraints of the existing terminal infrastructure. The entire project was executed and coordinated using Building Information Modeling (BIM).

PROJECT DETAILS

System Components

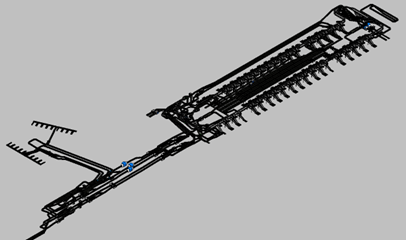

The full BHS system includes:

- Nine (9) fully automated in-line standard 3 screening machines

- Three (3) Tilt-Tray Sorters (TTS)

- Early Bag Storage (EBS) conveyor lanes

- 146 make-up chutes

Terminal Configurations

Future ROWs were planned within the existing structure to accommodate three additional HBS machines, linking the new screening facility in Terminal 2 with sortation loops in Terminal 3. Terminal 3 includes two main check-in islands, each connected to two Standard 3 screening machines for in-line security processing. Once screened, baggage enters two TTS loops and is sorted into the designated make-up chutes.

Terminal 2 features four reversible check-in islands designed for operational redundancy. These connect to two new ticketing lines, which divert baggage to four screening lines feeding into the new Standard 3 machines. Cleared baggage for Terminal 2 is routed to the new make-up facility in the west, while baggage for Terminal 3 is transported via existing tunnel conveyors to existing make-up chutes.