Overview

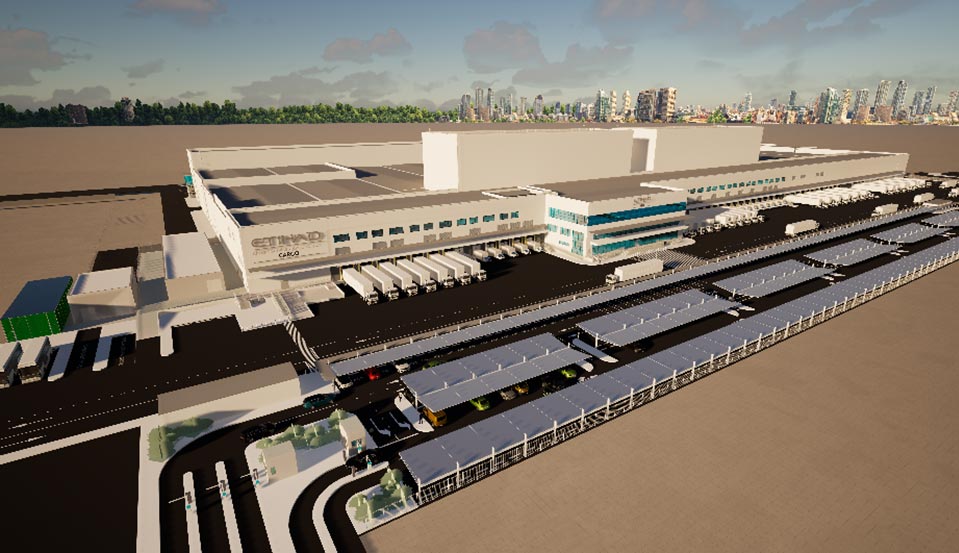

Etihad Airport Services Cargo (EASC) retained BNP to provide data analysis, design, simulation, engineering, tendering, and construction support for a new air cargo terminal (EMCT) and a forward cargo staging facility.

The main cargo terminal will handle 1 million tons of cargo per year and cover 70,000 square meters. A smaller fully airside forward transfer facility, covering 6,500 square meters and handling 250,000 tons per year, will support high transit volumes and help reduce pressure on the main cargo terminal.

Project Development

BNP work began with the development of a high-level concept of operations, conceptual building and system design, and an in-depth analysis of existing processes and data, down to each AirWayBill. The initial concepts were evaluated, and a preferred concept was selected for further development with an architect/engineer (ADPi/Meinhardt) that the airport separately retained.

The design was reviewed with the stakeholders and coordinated with the architect/engineer in 3D using BIM.

Tender Support and Construction

BNP supported EASC with the tendering of the MHS and evaluation/selection of the supplier.

The project is currently under construction, with the MHS being provided by Lodige Industries. The EMCT cargo handling system features a ULD storage system comprising 34 dolly interface points and four elevating transfer vehicles, which service 1000 ULD storage positions.

PROJECT DETAILS

Main Cargo Terminal Design

The design incorporates:

- 34 Dolly interface points

- 4 Elevating Transfer Vehicles

- 1000 ULD storage positions

- 32 Lowerable Workstations featuring Automated Guided Vehicle distribution.

- 41 Truck docks equipped with dock levelers and scissor lifts to cater to a wide fleet mix, including roller trucks.

- 5,500 Consignment Storage Positions: 2 modules of Automated Storage and Retrieval Systems (ASRS), each containing 2,750 In-House-Pallet storage positions and 8 ASRS Cranes.

- The facility features a comprehensive end-to-end cool chain system that includes eight insulated dolly interfaces, 12 insulated truck docks—segregated for perishables (PER) and pharmaceuticals (PIL)—and two insulated scissor lifts for handling temperature-sensitive ULDs. It offers more than 1,000 pallet positions with humidity and temperature control across COL, CRT, and FRO ranges. Additionally, the system includes 80 cool ULD storage cells. For cargo processing, 16 workstations are distributed across four areas, dedicated to handling PER and PIL cargo at COL and CRT temperature levels.

- The dedicated mail sorting area includes a cross-belt sorter and 21 chutes for handling mail bags.

Forward Transfer Facility

The Forward Transfer Facility Cargo Handling System features a ULD Storage System consisting of the following:

- 17 dolly interface points, eight fully enclosed to accommodate the handling of COL and CRT ULDs.

- 4 ETVs servicing 600 ULD positions, of which 80 are temperature-controlled for storing COL and CRT Cargo.

- Integrated ULD Screening Capability.